How to Automate Case Entry

Overview

Case entry in dental labs is a repetitive, error-prone administrative process that frequently becomes a bottleneck. Every case requires mapping order data to your products, checking scan quality, determining due dates, scheduling production, and routing tasks to the right people. Manual entry introduces staff training overhead and periodic errors that ripple through the rest of the manufacturing process.

This article breaks down the core components of case entry automation—from product mapping to quality control—showing you what's possible when you automate manual data transcription and decision-making in your intake process.

In-N-Out: Understanding Case Entry

At its core, case entry is identical to accepting an order at a restaurant, such as In-N-Out.

A customer places an order. They describe what they want using either pre-defined options or their own terminology, and your goal is to translate the order to the items from your menu.

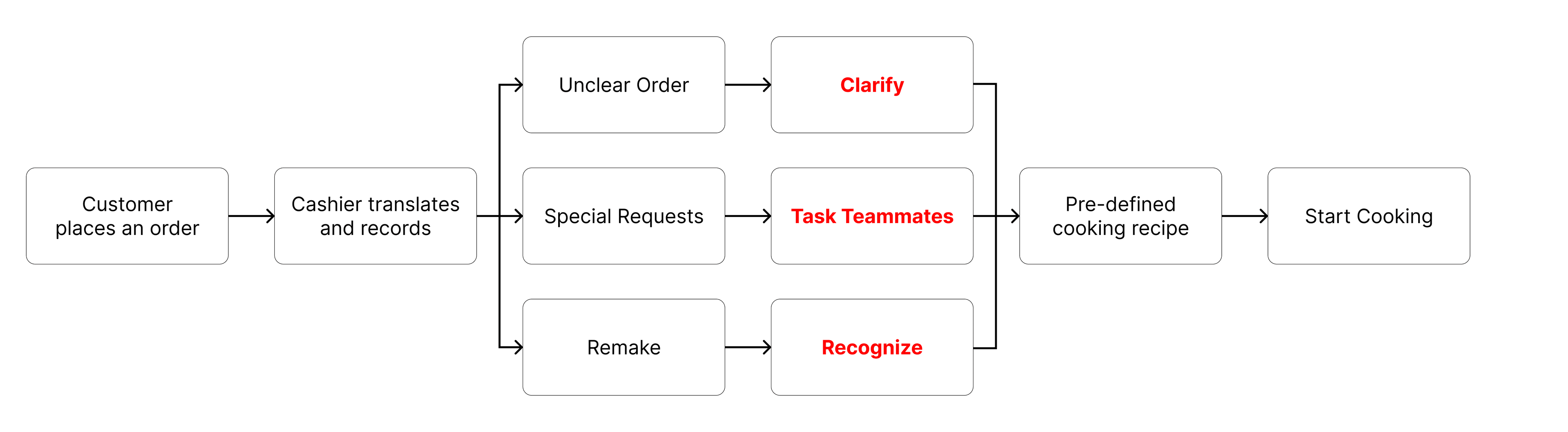

Here are all the things that happen during In-N-Out ordering:

- The customer describes an order (online or in-person)

- The cashier translates that order into In-N-Out's menu items and records it into the internal system

- If the order doesn't make sense or a customer didn't specify something, you return to the customer and request the missing pieces or clarification

- If the customer asks to do something special, need to add a task to do it

- If the customer comes back with the final product because it wasn't up to their standard, the restaurant remakes the product

- After the order has been placed, you need the cooking sequence - who will do what, when, and in what order. The sequence is based off of pre-defined recipes.

All of these steps map to the dental lab's order intake process almost 1-to-1. Let's see how.

The Typical Case Entry Flow

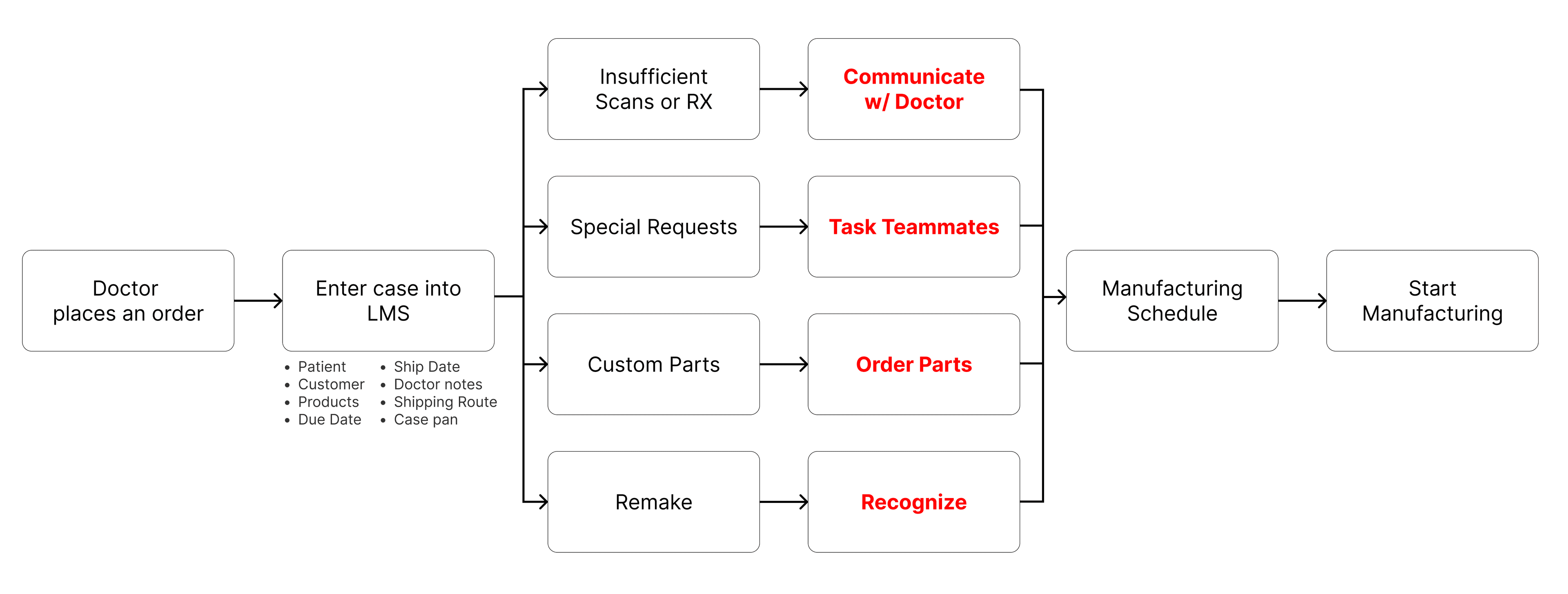

Here are all the same steps using the dental lab terminology:

- A doctor places an order (via scanner portals or a physical RX mailed to you)

- The case entry person needs to translate that order to your lab's products, figure out which customer this is, assign a due date, and put it into the lab's management system

- If the order inputs (RX or scans) are not sufficient, you need to contact the doctor and get all the necessary information before you proceed. This may require putting a case on hold until everything is resolved.

- If the RX requires you to order parts (e.g., custom abutments), then you need task someone with ordering those parts and to be able to track task completion

- If the doctor asks for, say, margin review or design approval, then you need to task someone with uploading the design and communicating with the doctor until the case can proceed with manufacturing. This may require putting a case on hold until the doctor approves proceeding.

- If this is a remake of the order you've already done, then you need to (1) recognize it, (2) ensure it gets billed correctly, and (3) ensure that the reason was provided and incorporate the requested adjustments into the new manufacturing round.

- After an order has been placed, you need the manufacturing schedule - which technicians will do what steps, when, and in what order.

The Problem

While your lab is relatively small, it's not a bad idea to enter cases manually – this is an opportunity to learn how it works, how to delegate tasks, and scale. But for labs processing hundreds of cases daily, this creates compounding issues:

Training overhead and churn

Administrative staff typically have higher turnover rates. Each new hire requires recruiting, onboarding, and 1-4 weeks of training. This is a lot of resources.

Bottlenecks during peak times

You can only process as many cases as you have trained staff members working at any given time. During high-volume periods, case entry becomes a production bottleneck.

Statistical error rates

No matter how well-trained your team is, human transcription and decision-making introduce errors. With enough volume, mistakes are inevitable: wrong products selected, wrong doctors assigned, missing auxiliary items, incorrect due dates. This necessitates downstream quality checks.

Operational capacity ceiling

The math reveals the hard limits. Case entry takes 4-5 minutes per case on average. With 480 working minutes in an 8-hour day, one fully-trained employee can process 96-120 cases per day, or roughly 2,900-3,600 cases per month at maximum capacity. But new hires don't start at maximum capacity. It takes about 3-4 weeks to fully ramp-up. The cost for one case entry hire:

- Employee cost: At $18/hour base rate, the total cost including payroll taxes, benefits, and overhead is approximately $45,000-$50,000 per year.

- Training cost: Depending on the amount of training it may take for the new employee, you need to calculate the trainer's time spent and the opportunity cost of that time.

This is the ideal scenario where an employee does nothing but case entry all day. In reality, most labs mix responsibilities—the same person handles case entry, invoicing, and customer support calls. That means you need more than one person covering case entry, which multiplies these costs and introduces additional variables to consider:

- What if that employee is sick or takes a vacation? Case entry stops or gets backed up. You're scrambling to cover or cases pile up, which wastes your turnaround times - one of the biggest competitive advantages a lab can have.

- What if you hit peak season and/or case volume spikes? Case entry becomes the bottleneck. Your operational team has capacity, but cases sit in the queue waiting to be entered. If you decide to hire someone, it will take time for ramp up and they may not be a good fit after all. Manual case entry puts a cost on your growth.

- What if it's a slow season and case volume drops? You're paying full-time wages for someone who's underutilized, sitting idle between cases.

In the end, your staff spend hours daily on repetitive data entry, and your lab's intake capacity is artificially limited by how many people you can train and retain.

How PilotLMS Automates the Entire Case Entry Process

PilotLMS eliminates manual case entry by automating every decision point from scanner portal to production floor. Here's how it maps to the typical case entry workflow.

Want to Read the Full Guide?

Download the complete article to learn about:

- ✓How PilotLMS automates the entire case entry process

- ✓Handling insufficient inputs and ordering parts

- ✓Remake recognition and automated handling

- ✓Creating automated manufacturing schedules

- ✓Real-world outcomes and efficiency gains

Free download • No credit card required